Better performance of slag concrete exposing to high temperatures

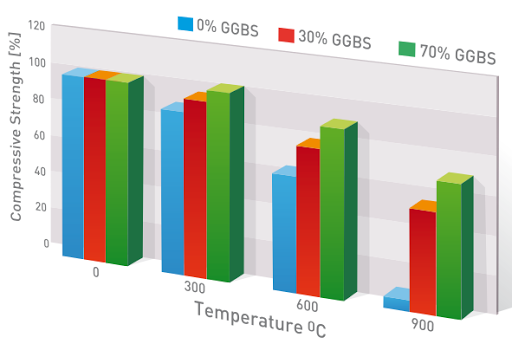

Concrete made with GGBS cement is much better than concrete made with 100% OPC at maintaining its compressive strength when exposed to high temperatures.

OPC specimens heated to 400 °C or above have been shown to exhibit severe cracking to the point of disintegration after a few days. However, it was found that concrete made with blends of 35%, 50% and 65% GGBS performed much better. In the GGBS specimens there was no visible cracking after exposure to the higher temperatures. The concrete with 100% OPC degraded to powder over the following year, while the concrete made with GGBS maintained its strength over the same period.

Further studies showed that after exposure to 900 °C concrete with 0% GGBS maintained 6% of its original strength, concrete with 30% GGBS maintained 54% of its original strength and concrete with 70% GGBS maintained 70% of its original strength.

Date source: Ecocem.

How does slag improve the resistance to fire damage?

Why concrete made with GGBS has better resistance to fire damage? It is generally agreed that above 400 °C Ca(OH)2 which is the hydration products of OPC decomposes into CaO and H2O, then on cooling CaO and left H2O rehydrates into Ca(OH)2 which needs more space than CaO causing the concrete to crack and degrade. With the addition of GGBS into concrete, hydration product Ca(OH)2 is generally reduced compared with concrete made with 100% OPC, thus improving the performance of resisting fire damage.

Reference: Ecocem report–Technical Performance