Theoretical background: see chapters 3 and 4 in Lieven Machiels’s PhD thesis (2010). Sample preparation method modified from Machiels et al. (2008).

Representative sampling

The mineralogy and glass content of slags depend largely on the mode of cooling of the slags, e.g. slow cooling in a slag pot can result in a large amount of crystalline phases, and fast granulation in water can result in high glass content. A mineralogical analysis will thus only represent the mineralogy of a slag system for a certain grade of cooling and strongly different results can be obtained when cooling conditions are different between the different batches.

Even in a single slag pot, mineralogy and glass content can vary strongly. Taking a sample representative for a slag pot can be done by performing the sampling after a first size reduction of the bulk material or, by mixing representative parts of the slag pot (sides of the pot, center, near cracks, in center of slags, etc.)

Crushing

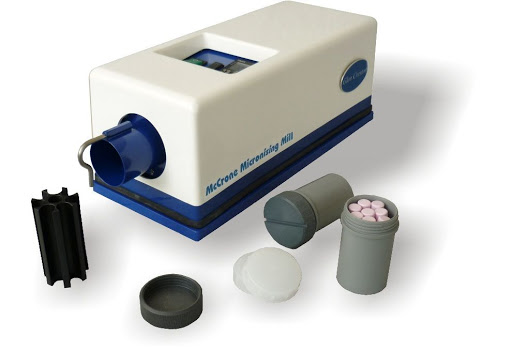

A grain size of <10 micron is required for quantitative X-ray diffraction (Rietveld). To avoid amorphisation of the sample during grinding, wet milling is done in a McCrone Micronizing mill. Before grinding in the McCrone Mill, the samples are crushed and passed through a 500 micron sieve.

Take representative amounts of sample (50-100 g). Crush the sample by hand in a porcelain mortar. Use shock impact for grinding, avoid shearing. A jaw crusher can be used, but automatic milling devices which could induce shear stress of amorphisation such as ball mills should be avoided!

Micronizing of the sample

– Weigh 2.7 g of sample; add 0.3 g (10%) of ZnO internal standard. Note down the exact weights, they will be used in the calculations

– Micronize the samples in a MeCrone Micronizing mill using 5 ml of ethanol (methanol) as grinding agent and a grinding time of 5 minutes for soft material (e. g. limestones) up to 10 minutes for hard materials (eg. quartzites, slags). Since methanol tends to react with some artificial minerals, and as it is toxic, ethanol is preferred. To ensure that samples are ground up to < 10 micron, the size required for X-ray quantification, the grain size is best checked by (wet) laser diffractometry.

– After micronizing, recuperate the sample in porcelain cups. Cover the cups with plastic foil, because recovery of powder from the porcelain when dried is difficult. Wash with methanol to recuperate as much as possible of the sample.

– Dry for one—two days under a fume hood (methanol is toxic).

Preparation for X-ray diffraction

– Dried samples are gently disaggregated in an agate mortar and passed through a 250 micron sieve, to ensure good mixing of sample and ZnO standard.

– +/- 0.5 g of sample is needed for the X-ray analysis. Side-loading with frosted glass is recommended to fill sample holders, to prevent preferential orientation of fibrous zeolites and clay minerals. Sample holders are gently tapped while filling, to ensure good packing of the grains. Alternatively, back loading is used.

The content is offered by Dr. Lieven Machiels