The rheology of cementitious material paste is complex and difficult to be investigated. One value of rheology is yield stress. The best method to measure the yield stress in laboratory is using the vane method. However, there is no much literature reporting an practical and detailed testing protocol to measure the yield stress of cement paste. Here I briefly introduce the protocol I am using at our laboratory.

To obtain stable and reliable results, we should choose the same container and the same mixing procedure. We normally use a plastic beaker with a volume 500 ml, for the beaker has enough diameter and depth for the test without the influence of boundary effect, i.e. the diameter is two times larger than the diameter of the vane. For each test, 270 g of cement is mixed with relevant water at the required water to cement ratio. For the mixing, a high-shear mixer is applied with a shear rate 800 RPM for 2 minutes.

As soon as the well mixed paste is ready, let the blades of the vane of rheometer immerse in the paste. Make sure the top surface of the paste staying between the two lines labeled on the shaft.

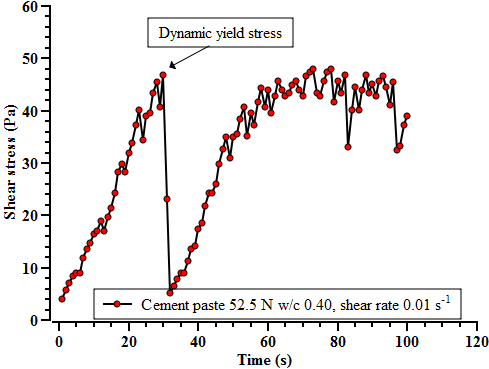

The principle to measure the yield stress is applying a very low fixed shear rate on the paste, e.g 0.02-0.001 1/s, then the shear stress linearly increases till yield stress. As shown in the recorded data (Fig 1), the shear stress drops remarkably when the paste is yield, thus the maximum stress is the yield stress, i.e. dynamic yield stress.

Fig. 1. Measuring device: HAAKE™ VT550 (ViscoTester VT550), CR (Controlled shear Rate): 0.01000 1/s; t 120.00 s; T 20.00 °C.

If the maximum stress does not occur within the testing period, longer time or higher shear rate may be tried. It is also worth to note that this method gives good result for paste with yield stress higher than 10 Pa.

4 replies on “The right protocol to measure yield stress of cement paste”

Did you get a chance to look at the shear rate data? I think it may be better to exclude the possibility of wall slip…

I used 0.01 1/s in the experiment of this post.

After yielding, the structure of cement paste usually break down gradually, but this result breakdown abruptly, so it is better to exclude the possibility of wall slip.

As the HAAKE™ VT550 is the stress-controlled rheometer as I know, so when you apply a shear rate, the instrument use a feedback loop to give you what you want. It will be worthy to check the raw data that whether the instrument reach the set shear rate value over time.

VT 550 is a shear rate controlled instrument.